Views: 1 Author: Site Editor Publish Time: 2025-10-22 Origin: Site

A smooth, quiet ride is the hallmark of a well-maintained vehicle. While we often credit the suspension or tires for this comfort, an unsung hero works tirelessly under the hood: the engine mount. This crucial component plays a vital role in your car's performance and longevity. Understanding its function, recognizing failure signs, and knowing the associated costs can save you from significant headaches and expensive repairs down the line.

This guide will delve into the world of the car engine mounting system. We will explore what an engine mount does, why it's so important for your vehicle's health, and what to expect regarding the changing engine mounts cost.

So, what exactly is an engine mount? At its core, an engine mount is a specialized bracket that secures your vehicle's engine and transmission to the chassis. However, its job is far more complex than simply holding the engine in place. Its primary functions are twofold: to support the engine's weight and, more importantly, to absorb and dampen the vibrations and shocks produced by the engine during operation.

Without a proper engine mount, the immense vibrations from the engine would transfer directly to the car's frame, creating an incredibly noisy and uncomfortable driving experience. This constant shaking would not only be unpleasant for passengers but would also cause premature wear and tear on other vehicle components. Therefore, the car engine mounting system is essential for both performance and comfort.

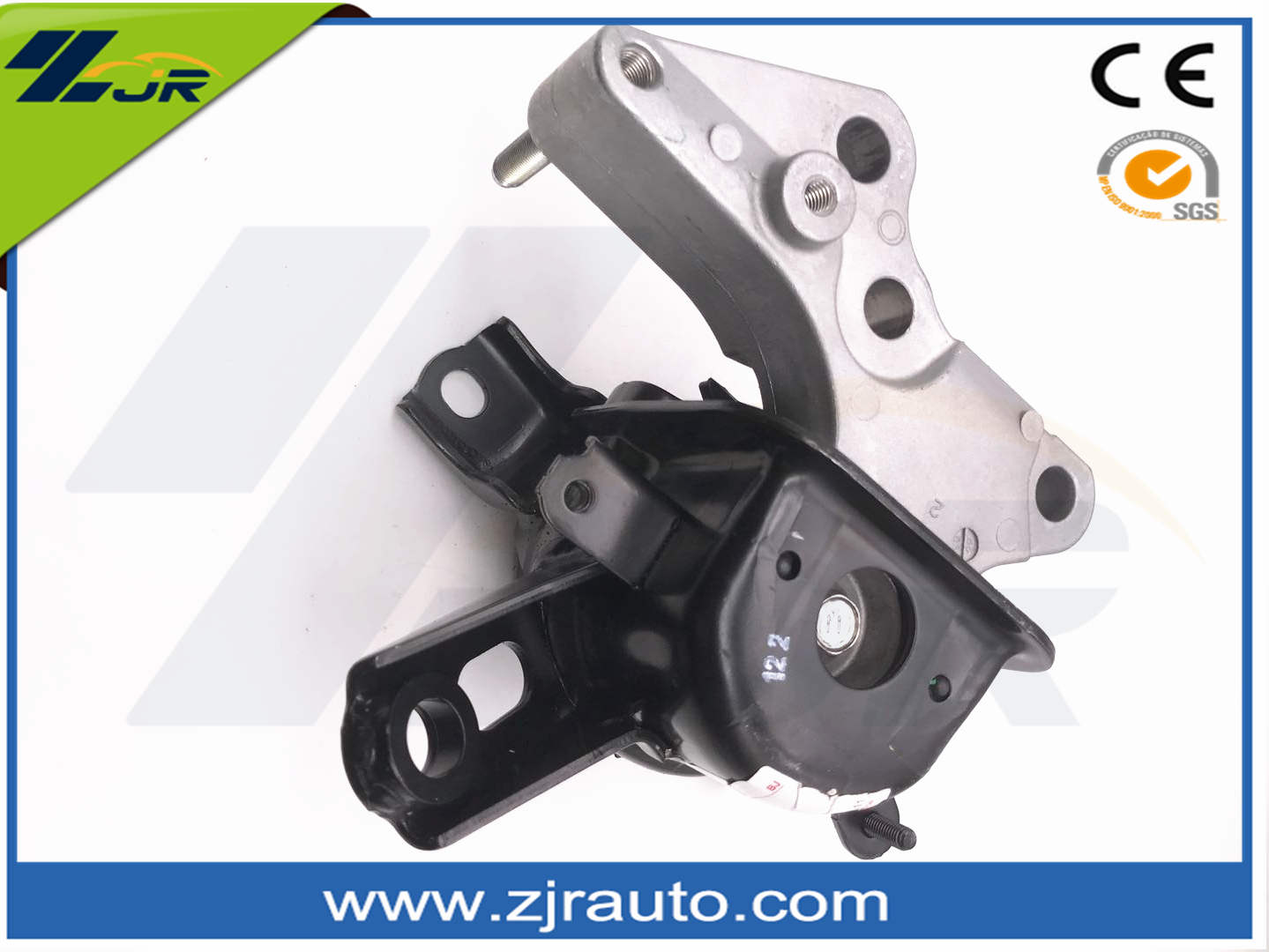

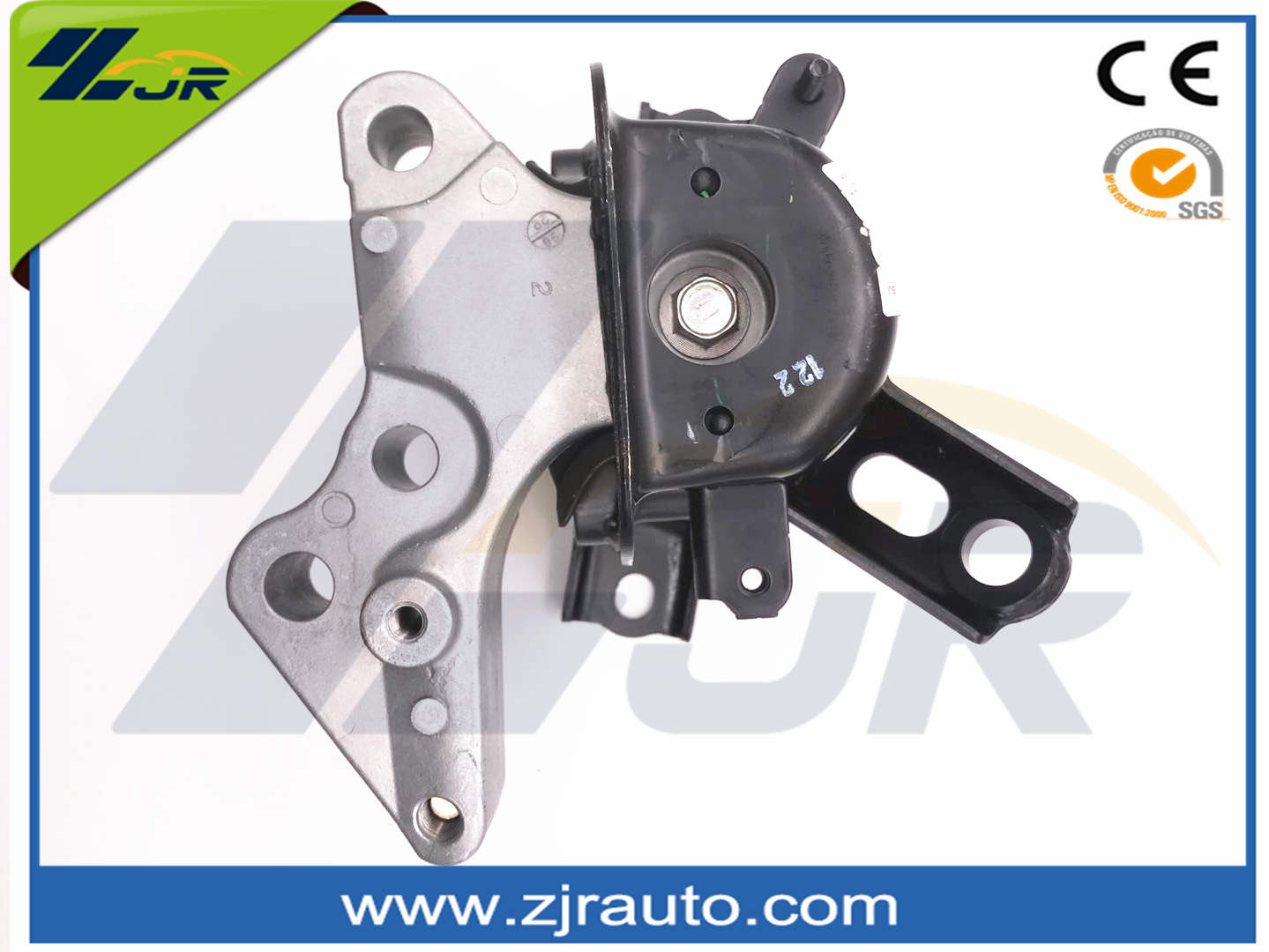

Most engine mounts consist of a metal frame with a rubber or fluid-filled block.

Metal Frame: Provides the structural strength needed to hold the engine securely to the vehicle's subframe.

Rubber or Fluid Core: This is the vibration-absorbing heart of the engine mount. The rubber is specially formulated to be firm enough to support the engine's weight but flexible enough to isolate its vibrations.

When the engine runs, it naturally vibrates. The rubber core of the engine mount flexes and absorbs these vibrations, preventing them from reaching the cabin. This simple yet effective design is fundamental to modern vehicle engineering, ensuring a smooth and stable ride.

Like any part made of rubber, an engine mount will wear out over time due to constant stress, heat, and exposure to automotive fluids. When an engine mount fails, it can no longer do its job effectively, leading to a host of noticeable symptoms. Being aware of these signs can help you address the issue before it causes more significant damage.

The most common symptom of a failing engine mount is a noticeable increase in vibration felt inside the cabin, particularly when the car is idling or accelerating. If you feel a rough, rumbling sensation through the steering wheel, floor, or seats, a worn-out car engine mounting component is a likely culprit.

A healthy engine is held firmly in place. When an engine mount is broken or worn, the engine can shift and move excessively during acceleration, deceleration, or gear changes. This movement can result in clunking, banging, or thudding sounds as the engine block makes contact with other parts in the engine bay. These impact noises are a clear red flag.

In severe cases, you might be able to visually see the engine moving or lurching when it's revved. With the hood open and the car in park (with the parking brake engaged), have a friend gently press the accelerator while you observe the engine. Any significant rocking or shifting is a definitive sign of a compromised engine mount.

A loose engine can put immense strain on connected parts. Radiator hoses, exhaust pipes, and drive belts can be stretched, twisted, or broken due to excessive engine movement. If you find yourself repeatedly repairing these related components, the root cause could very well be a bad car engine mounting system.

If you've identified symptoms of a failed mount, your next question is likely about the changing engine mounts cost. The final price can vary significantly based on several factors, including your vehicle's make and model, the labor rates in your area, and the type of replacement engine mount used..

The changing engine mounts cost is composed of two main elements: the cost of the part itself and the cost of labor to install it.

Cost Component | Average Price Range (USD) | Factors Influencing Cost |

|---|---|---|

Part Cost | $50 - $250 per mount | Vehicle make/model, OEM vs. aftermarket, type (rubber, hydraulic) |

Labor Cost | $100 - $400+ | Vehicle complexity, accessibility of the mount, mechanic's hourly rate |

Total Cost | $150 - $650+ per mount | Combination of part and labor factors |

Most vehicles have between three and four engine mounts. While it's sometimes possible to replace only the one that has failed, mechanics often recommend replacing them in pairs or as a full set. This ensures balanced support and prevents the new engine mount from being put under excessive strain by older, worn mounts. The overall changing engine mounts cost for a full set can therefore range from $400 to over $1,000. While this may seem steep, it is a necessary investment to prevent far more costly engine or frame damage.

When considering the changing engine mounts cost, it might be tempting to opt for the cheapest available part. However, the quality of the replacement engine mount is paramount. A low-quality car engine mounting part may fail prematurely, leading you right back to the repair shop.

Durability: Made from high-grade rubber and steel to withstand years of stress and engine heat.

Optimal Vibration Dampening: Engineered precisely for your vehicle's specifications to provide the smoothest ride possible.

Perfect Fit: Ensures a secure connection to the engine and chassis, preventing movement and potential damage.

Investing in a quality car engine mounting solution is an investment in your vehicle's long-term health and your own driving comfort.

A: An engine mount serves two primary purposes in a vehicle. First, it physically secures the engine and transmission assembly to the car's frame, holding it firmly in place. Second, and just as importantly, it acts as a shock and vibration absorber. The engine mount is designed with a rubber or fluid-filled component that isolates the vibrations produced by the running engine, preventing them from transferring to the chassis and into the passenger cabin. This ensures a smoother, quieter ride and protects other vehicle components from damage caused by excessive vibration.

The engine mount is a small but mighty component that is essential for a safe, smooth, and reliable driving experience. From supporting the engine's weight to absorbing its vibrations, its role cannot be overstated. Recognizing the signs of failure and understanding the factors that influence the changing engine mounts cost empowers you to make informed decisions about your vehicle's maintenance.

When it comes time for a replacement, choosing a high-quality part is crucial. For top-tier components that deliver exceptional durability and performance, we highly recommend zjr auto. Their commitment to quality ensures that your car engine mounting system provides the reliability and smoothness you expect. With a focus on precision engineering, zjr auto produces engine mount solutions you can depend on.

For inquiries or to find the right engine mount for your vehicle, contact the experts at zjr auto.

Email: info@zjrauto.com

Phone: +86 13702583315

If you want to know more, click on the article below:

High-Quality Control Arm Bushings for Superior Vehicle Performance

Everything About Your Engine Mount: A Key Car Part

Understanding Suspension Bushes: A Complete Guide To Auto Spare Parts And Vehicle Performance